how to enhance the reflow profile in the PCB process?

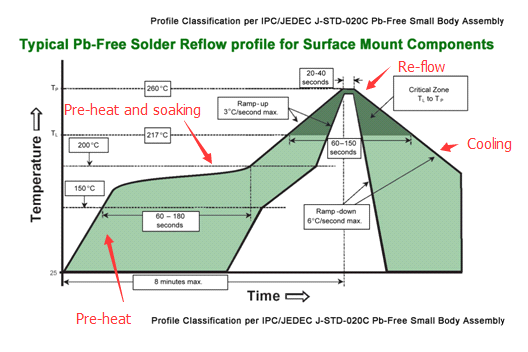

According to the referral by the IPC organization, the common Pb-free solder reflow account is revealed listed below.

The ENVIRONMENT-FRIENDLY location is the appropriate variety for the entire reflow procedure. Does it suggest that every area in this ECO-FRIENDLY location should fit your board reflow application? The solution is definitely NO!

The PCB thermal ability is various according to the product kind, density, copper weight, and also the form of the board. It is additionally rather various when the parts take in the warmth to heat up. Large parts might require even more time to warm up than tiny ones. So, you have to evaluate your target board initially prior to developing a distinct reflow account.

- Make an online reflow profile.

- An online reflow profile is based upon the soldering concept, the suggested solder account from the solder paste maker, dimension, density, cooper weight, layers of the board and also dimension, and also the thickness of the parts.

- Reflow the board as well as gauge the live thermal account at the same time.

- Inspect the solder joint top quality, PCB, and also element condition.

- Burn in an examination board with thermal shock as well as mechanical shock to examine the board's dependability.

- Contrast real-time thermal information with the online profile.

- Change the criterion configuration and also examination numerous times to locate the ceiling as well as profits of the real-time reflow profile.

- Conserve enhanced specifications according to the target board's reflow spec.