Improving heat dissipation in compact PCBA (Printed Circuit Board Assembly) designs is crucial to ensure the reliability and longevity of electronic devices. Here are several strategies to enhance heat dissipation within such designs:

-

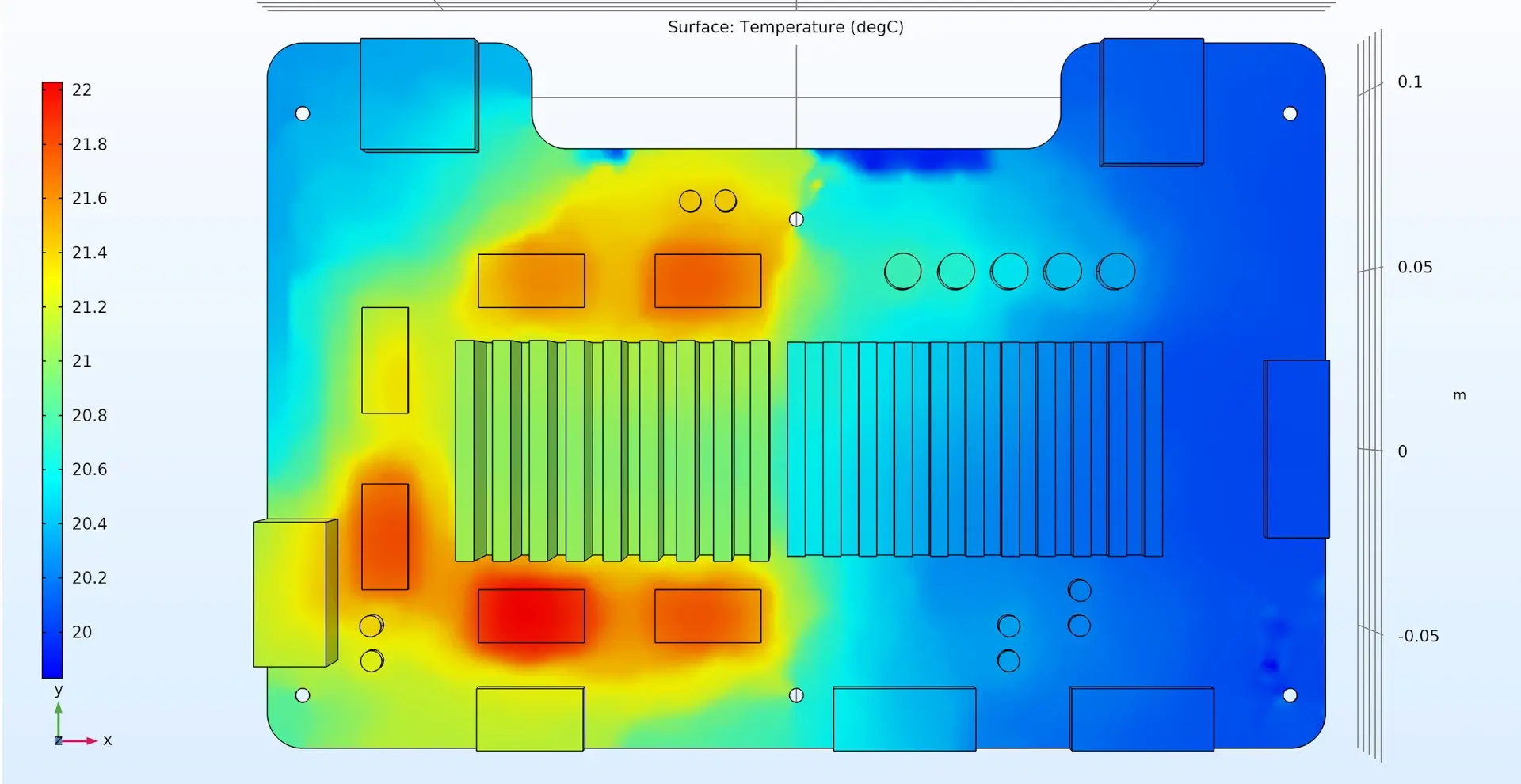

Thermal Analysis and Simulation: Utilize thermal analysis and simulation software to identify and mitigate potential heat accumulation areas on the PCB. This proactive approach allows for optimized component placement and the implementation of heat dissipation solutions during the design phase.

-

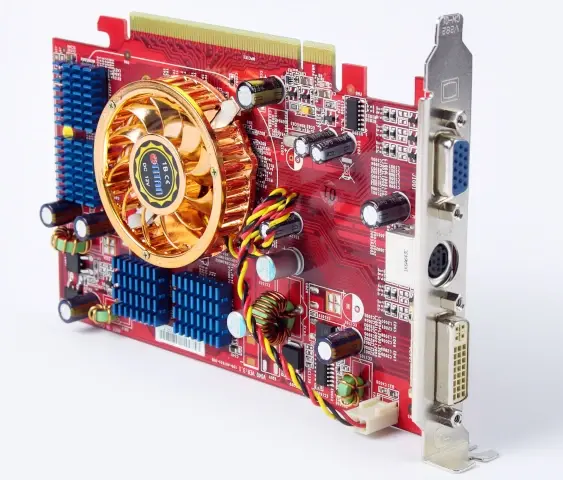

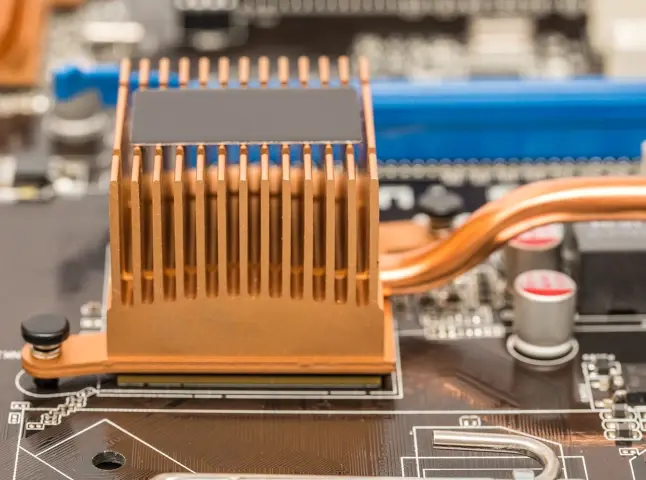

Heat-Sinking Components: Incorporate heat sinks on components that generate significant heat, such as voltage regulators, power transistors, or microcontrollers. Additionally, utilizing thermally conductive pads or compounds between components and heat sinks improves thermal transfer.

-

Optimized PCB Layout: Design the PCB layout to minimize heat-generating components' proximity, reducing thermal interference. Clustering high-power components and providing adequate spacing between them can prevent localized heat buildup.

-

Thermal Vias: Implement thermal vias to improve heat dissipation from important components to internal and external copper layers. This aids in conducting heat away from sensitive areas to the PCB's outer layers, where it can be dissipated more effectively.

-

Advanced PCB Materials: Choose PCB materials with high thermal conductivity, such as metal-core PCBs (MCPCBs) or thermally conductive substrates. These materials can efficiently transfer heat away from critical components.

-

Adequate Airflow and Ventilation: Design the enclosure to allow for proper airflow around heat-generating components. Incorporating ventilation holes, fans, or natural convection paths can facilitate efficient heat dissipation.

-

Heat-Dissipating Coatings: Consider using thermally conductive coatings or encapsulants that aid in spreading and dissipating heat.

-

Efficient Component Selection: Opt for power-efficient and cooler-running components when feasible. Selecting components with lower power dissipation or higher efficiency can significantly reduce overall heat generation.

-

External Heat Sinks or Heat Spreaders: If space permits, consider integrating external heat sinks or heat spreaders into the compact design to facilitate additional heat dissipation.

-

Thermal Management Considerations: Properly factor in thermal management considerations during the design phase, including proactive thermal analysis, prototyping, and testing to verify the effectiveness of heat dissipation solutions.

By implementing these strategies, you can significantly enhance heat dissipation in compact PCBA designs, thereby improving overall system performance, reliability, and longevity.