5expert tips for extending the life of your soldering iron tip.

Here are 5 expert tips to extend the life of your soldering iron tips.With more than 15 years of hands-on experience in electronics and soldering, I am here to share my experience and advice on what you can do to extend and improve the life of your soldering iron tip so that it solders well and lasts a long time.

Causes of soldering iron tip corrosion

There can be several reasons for tip corrosion and solder not sticking to the tip. Here are some reasons:

- Quality of Solder and Flux Used : The composition and quality of the solder wire used for soldering can affect the life of the soldering iron tip. Likewise, the activity of the flux used will affect the lifetime of the tip.

- Prompt temperature The temperature set by the soldering iron tip will also affect the oxidation and life of the soldering iron tip. Tin-lead solder wire has a lower melting point than lead- free solder wire . Therefore, it is necessary to increase the temperature in the lead welding process, which in turn accelerates the oxidation and corrosion of the lead.

-

Inexperience, Poor Welding Habits Beginners and inexperienced technicians often solder the wrong way. For example, they may not set the tip temperature as required.

-

How to Extend the Life of Your Soldering Iron Tips - 5 Expert Tips

Here are 5 simple tips you need to follow:

-

Use high quality solder wire and flux

Never compromise on solder wire and flux quality. Try using droplet solder wire and make sure you use lightly activated flux ( RMA flux ).

Alpha Cookson solder wire is trusted and used by most of the world's top electronics companies .

2. Use a good quality solder station or iron

Inexpensive and high-quality soldering iron, the soldering iron tip of the soldering iron does not have a long service life, and even the performance of the soldering iron is not ideal. Therefore, it is recommended to use only top-of-the-line and trustworthy soldering irons or stations.

Bounty Soldering satations and Irons are widely used and trusted around the world.

3. Use a cleaning sponge or copper wool

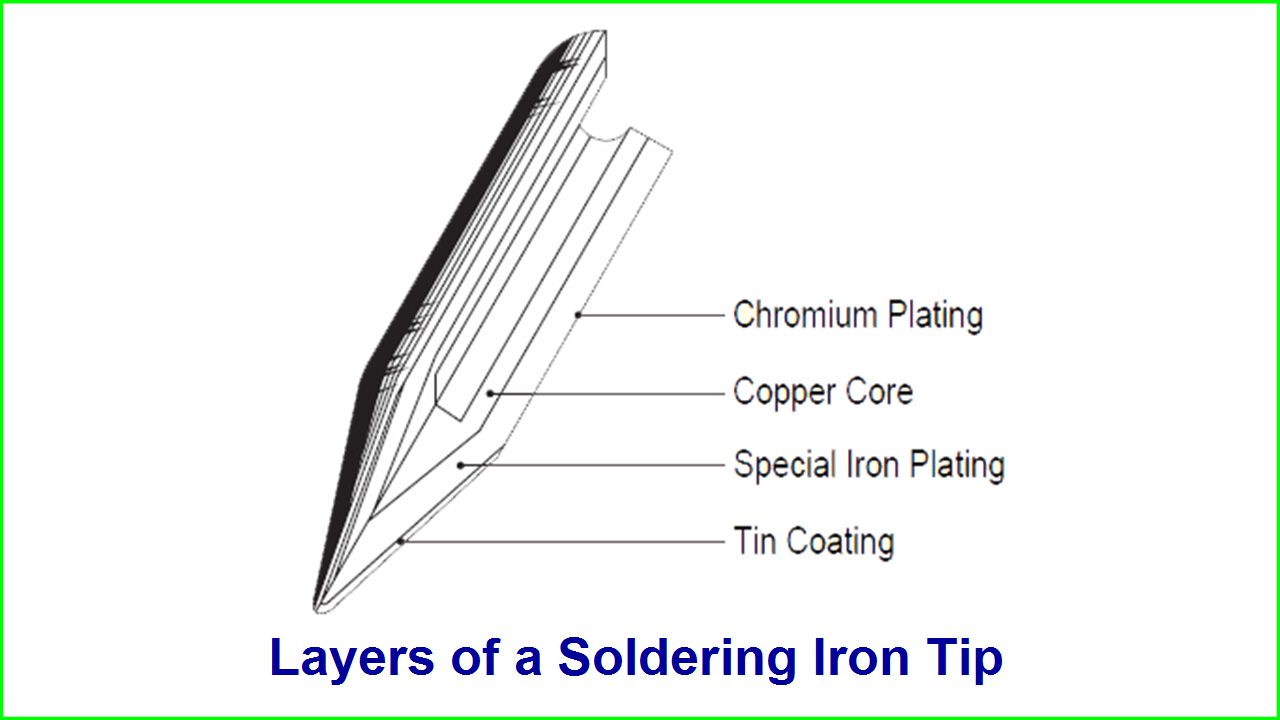

Many technicians use sandpaper or a file to remove oxide from the tip of the knife. This can damage the tin coating on the tip. Use a damp cleaning sponge or a non-abrasive cleaning tool such as copper wool.

4. Maintain proper tip temperature

Maintaining proper tip temperature plays a very important role in preventing tip oxidation and corrosion. Therefore, it is recommended to maintain proper tip temperature and not overheat. The faster the heating, the tip will be oxidized and corroded, which will affect its life.

5. Tin the tip after soldering

Don't just turn off the iron at the station when you're done welding, put the iron on the stand. It is important to tin the tip before leaving the workbench.

Tinning the tip means turning off the iron or station and applying some solder to the tip, then placing it on the standoff. This will prevent oxidation.