12 Easy Tips to Improve Your PCB Desoldering

-

Use Quality Desoldering Tools

- Invest in high-quality desoldering tools such as desoldering pumps, desoldering wick, and desoldering stations with adjustable temperature controls.

-

Proper Component Heating

- Apply heat directly to the component lead or pad while removing solder to avoid overheating surrounding components.

-

Keep the Soldering Iron Tip Clean

- Regularly clean the soldering iron tip to ensure efficient heat transfer during desoldering.

-

Use Flux

- Apply flux to the solder joint before desoldering to improve solder flow and aid in the desoldering process.

-

Controlled Temperature

- Maintain a controlled and suitable temperature to avoid damaging the PCB and components during desoldering.

-

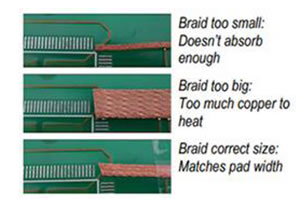

Desoldering Braid/Wick Technique

- Master the technique of using desoldering braid or wick to remove excess solder and clean up the pads.

-

Work in a Well-Ventilated Area

- Ensure proper ventilation to avoid inhaling fumes produced during the desoldering process.

-

Inspect for Remaining Solder

- After desoldering, carefully inspect the joints to ensure no residual solder remains, which could cause shorts or unreliable connections.

-

Use ESD Precautions

- Employ Electrostatic Discharge (ESD) precautions to protect sensitive components and prevent damage during the desoldering process.

-

Practice Patience

- Take your time and work methodically during the desoldering process to avoid damaging the PCB and components.

-

Component Removal Sequence

- Follow a strategic sequence for removing components to minimize heat exposure and prevent damage to nearby components.

-

Training and Skills Development

- Provide training and continuous skills development for personnel involved in desoldering to ensure proficiency and precision in the process.

These tips can significantly improve your PCB desoldering efficiency and help maintain the integrity of the PCB and its components.