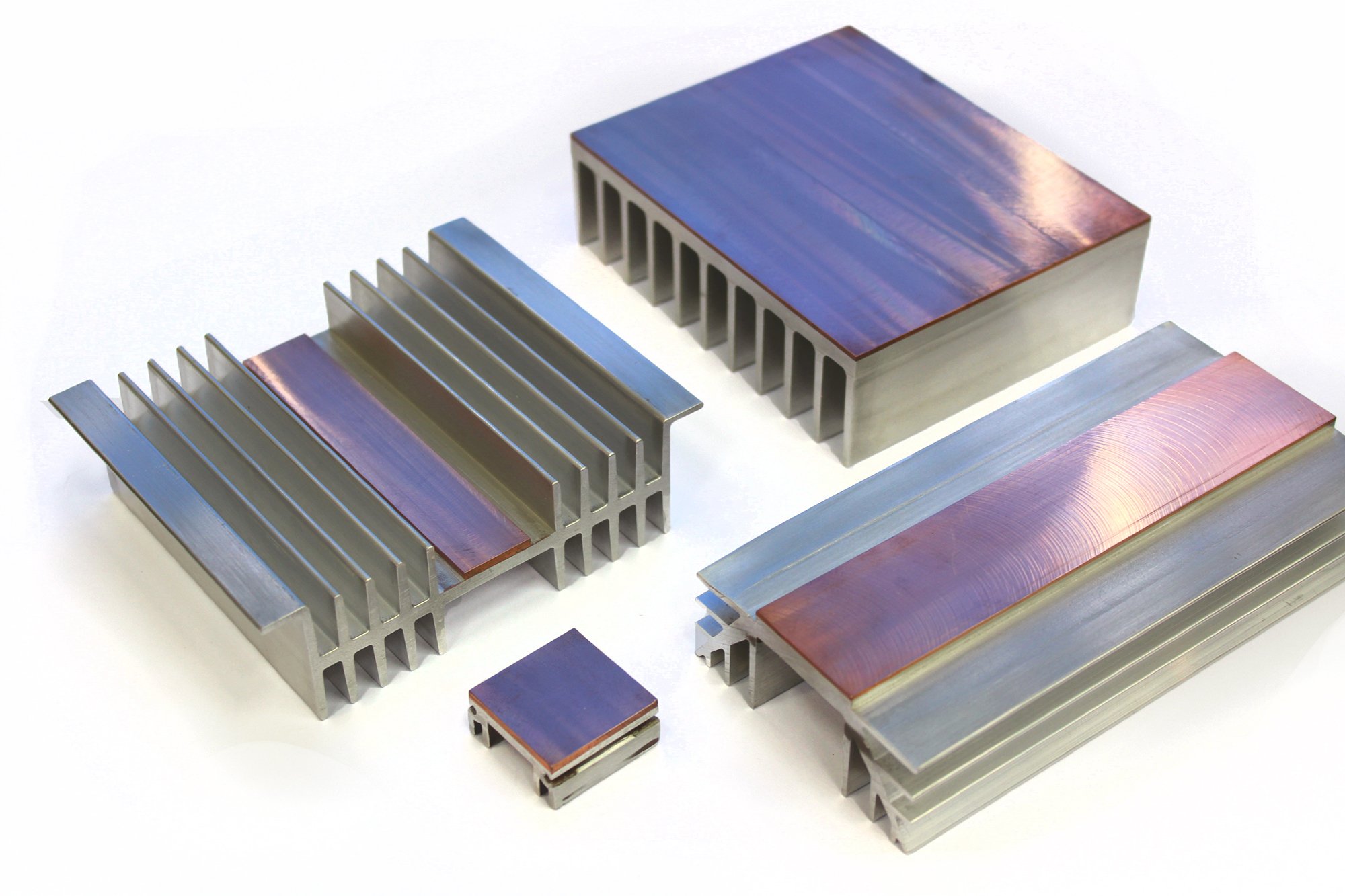

A heatsink is an electronic component that prevents components on a circuit board from frying because of increased heat capacity. It is made of cold plates from materials with good thermal conductivity.

Generally, its components increase and direct the heat flow away from a hot device by widening its working area. After, it expands the fluid that travels across the widened area, raising the heat dissipation rate.

How does a heat sink work?

A heat sink works by moving heat away from a critical component. This is done in four basic steps:

- The source generates heat: This source may be any system that creates heat and requires the removal of said heat to function accordingly, such as mechanical, electrical, chemical, nuclear, solar, and friction.

- Heat transfers away from the source: In direct heat sink-contact applications, heat moves into the heat sink and away from the source via natural conduction. The heat sink material's thermal conductivity directly impacts this process. That is why high thermal conductivity materials such as copper and aluminum are extremely common in the construction of heat sinks.

- Heat distributes throughout the heat sinks: Heat will naturally travel through the heat sink via natural conduction moving across the thermal gradient from a high-temperature to a low-temperature environment. This ultimately means that the heat sink's thermal profile will not be consistent. As a result, heat sinks will often be hotter towards the source and cooler towards the sink's extremities.

-

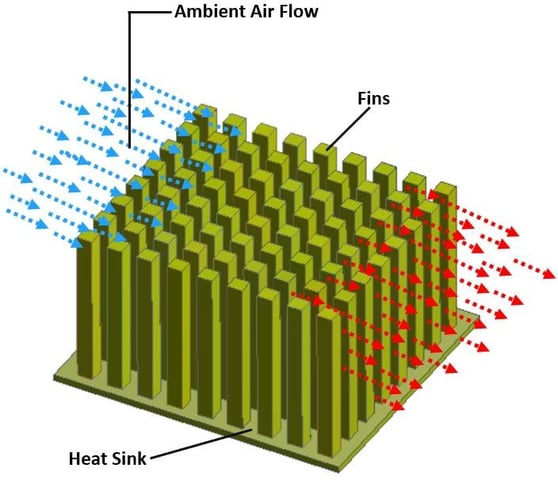

Heat moves away from the heat sink: This process relies on the heat sink's temperature gradient and its working fluid--most commonly air or a non-electrically-conductive liquid.

- The working fluid passes across the surface of the warm heat sink and utilizes thermal diffusion and convection to remove heat away from the surface and into the surrounding environment.

- This stage relies on, yet again, a temperature gradient to remove heat from the heat sink. Therefore, if the surrounding temperature is not cooler than the heat sink, no convection and subsequent heat removal will occur.

-

This stage is also where the total surface area of the heat sink becomes most advantageous. A large surface area provides an increased area for thermal diffusion and convection to occur.

Type of Heat Sink

There are three types of heat sinks: passive, active, and hybrid.

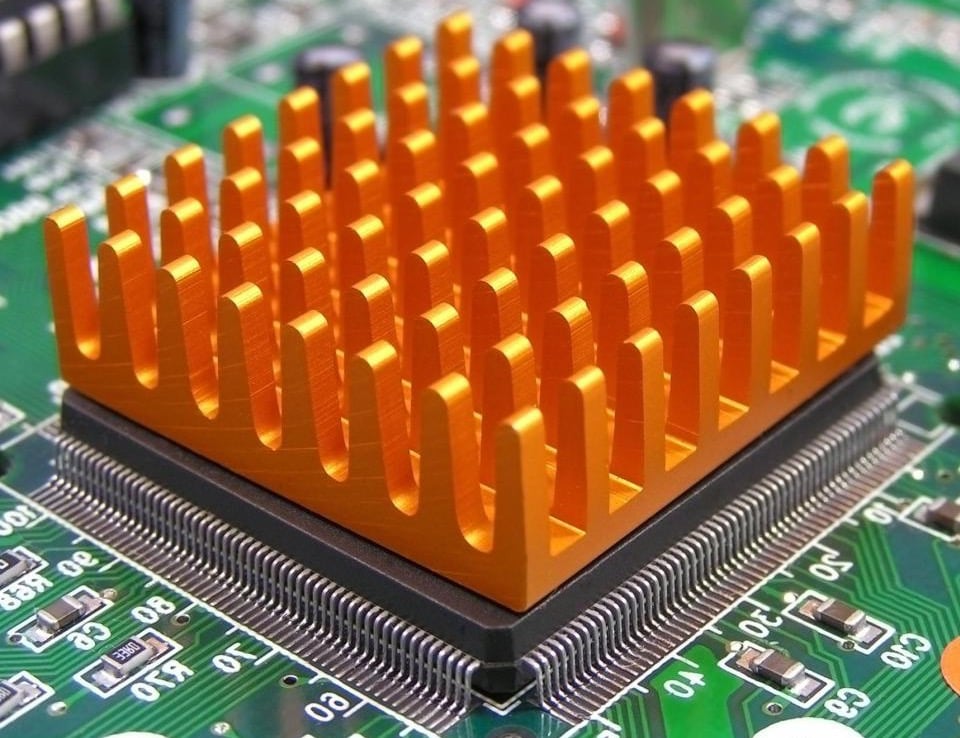

Passive heat sinks

Passive heat sinks rely on natural convection, meaning the buoyancy of hot air alone causes the airflow generated across the heat sink system. The benefit of these types of heat sinks is that they do not require secondary power or control systems to remove heat from the system. However, passive heat sinks are less effective at transferring heat from a system than active heat sinks.

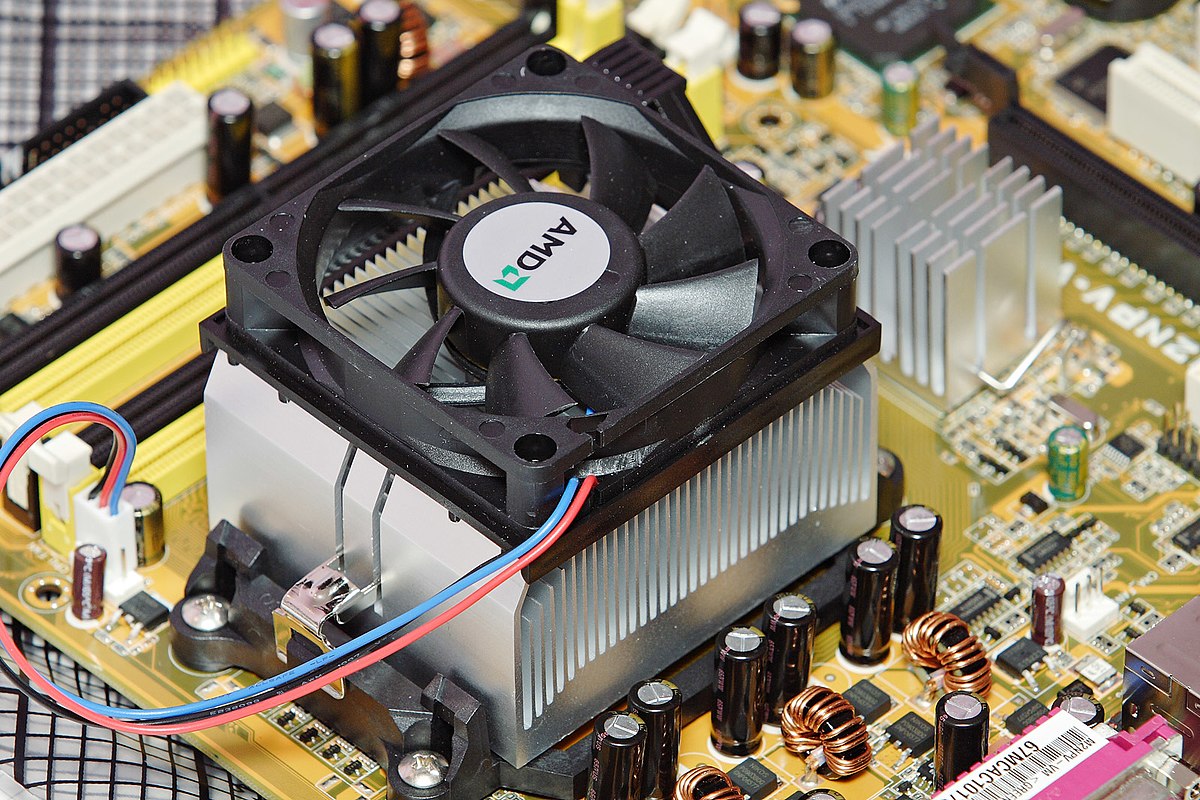

Active heat sinks

Active heat sinks utilize forced air to increase fluid flow across the hot area. Forced air is most commonly generated by a fan, blower, or even movement of the entire object.

An example of a fan producing forced air across a heat sink is the fan in your personal computer turning on after your computer gets warm. The fan forces air across the heat sink, which allows more unheated air to move across the heat sink surface, thus increasing the total thermal gradient across the heat sink system and allowing more heat to exit the overall system.

Hybrid heat sinks

Hybrid heat sinks combine some aspects of passive and active heat sinks. These configurations are less common, and they often rely on control systems to cool the system based on temperature requirements.

When the system operates at cooler levels, the forced air source is inactive, only cooling the system passively. Once the source reaches higher temperatures, the active cooling mechanism engages to increase the cooling capacity of the system.