Today’s high-speed digital systems and high-frequency RF circuits are found in everything from cellular phones to high-speed instruments and computer systems. The high-speed subsystems or high-frequency RF circuits radiate significant amounts of electrical interference.

This interference takes the form of both radio-frequency interference (RFI) and electromagnetic interference (EMI), and if left unmitigated, the RFI and EMI can cause system malfunctions, incorrect readings, and other detrimental effects.

To counter the effects, designers can employ various shielding techniques to basically put faraday shields around the radiating circuits. That is all well and good for the components on the surface of the printed circuit board (PCB), but emitted radiation also goes though the PCB and can affect circuits under the PCB. In addition to adding a shield on the top side of the PCB, careful attention to the circuit layout and the use of ground planes inside the PCB itself can go a long way toward reducing the emissions.

Additional PCB design techniques such as the use of suitable geometric land pads to enhance efficient soldering, minimizing component leads that pass through the PCB to reduce “antenna” effects, and reasonable distancing of intra-interference potentials, can all help reduce RFI and EMI.

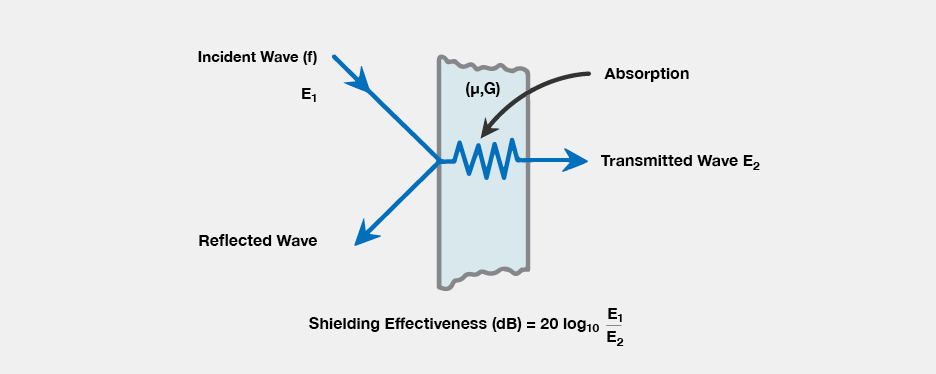

When an electromagnetic wave travels through space and impacts an electrically conductive object, several actions will take place – the wave will be reflected, the wave will be absorbed, a secondary wave will be created, or a combination of all three.

RF Shielding Effectiveness

Shielding effectiveness is expressed quantitively as dB –20log10 (E1/E2), where E1 is the value of the incident wave entering the shielding material and E2 is the value of the transmitted wave, that emerges from the shield (Figure 1).

The result provides a value representing the reduction in emitted EMI/RFI. The material used for the shielding is a key factor in determining the attenuation of the EMI/RFI, and thus the difference between E1 and E2.

Fig.1

There are many design and analysis tools that can help designers simulate and analyze the radiated emissions even before the hardware is created. Additionally, there are tools and probing techniques that can measure the emissions, both prior to and after shielding has been added.

In addition to the tools, designers need standards with which they can compare their test results to determine if the shielding meets their requirements. See appendix A for a list of most of the shielding standards that are available.

Selecting The Right Shields

In general, designers can address their shielding challenges using a multi-step approach:

- Simulate as much as possible before any physical design.

- Use best PCB design guidelines and ground planes to minimize radiated energy of the prototype design.

- Select components with the appropriate characteristics – size, height, weight, etc.

- Post layout, take extensive radiation measurements to determine where the key sources of emissions are located and the size of the emissions.

- Select the best shielding material and style of shield to minimize the radiated energy.

- Mount the shield and take radiation measurements to verify that the shield performs the desired radiation reduction.

- Convert the prototype to a production-ready version (this may mean adjusting the PCB layout, changing components or other tweaks) and repeat steps 3, 4, 5, and 6.

Shielding Solutions - Many Options

Designers have many shielding options, from the types of materials used in the shields, to the physical structure of the shield itself. Additionally, the material thickness and the continuity of the shield itself also determine how effective the shield will be.

EMI shielding has traditionally been fabricated from metal sheets and formed into structures that surround and cover circuits that either need to be protected or are emitting unwanted radiation.

Steel, copper, and aluminum are viable materials – they are strong and rigid, but if too thin they can deform under the pressures automated handling systems. Once deformed, the metal shields often retain their deformed shape, and that may allow EMI to leak in or leak out of the shield.

When selecting a suitable shielding material there are several aspects that must be addressed:

- The electrical performance (the material’s ability to absorb the EMI/RFI radiation).

- The ability to endure expected environmental conditions (dust, moisture, etc.).

- The mechanical aspects (material behavior such as drawing, bending, cutting, etc.).

- The cost of material and the cost of shaping it and attaching it to the printed circuit board.

RF Shields Manufacturing

RF shields can be formed by bending metal, by casting the metals, by drawing the metal through a mold. Drawing the metal provides a consistent, robust result. The drawn technique yields a seamless shield frame that can withstand handling, transportation, and storage. Snap-on covers complete the shielding assembly.

regarding the shielding materials, as mentioned earlier – shields can be fabricated using steel, brass, nickel, brass, copper, stainless and aluminum. Masach offers pre-tinned steel and brass shields that are readily solderable to PCBs, resulting in considerable cost effectiveness.

Other shield materials would have to be plated post manufacturing. The seamless implementation of drawn shields results in good coplanarity, hence providing a virtual hermetic seal when mounted on a PCB. Additionally, a conductive grommet can be placed between the shield and the cover to close any physical gaps between the elements of the shield, thus minimizing EMI/RFI field leakage.

The drawn process offers designers a level of flexibility – in such that shields of the same X and Y dimensions can have slightly different heights, accommodating alternative component profiles mounted on the PCB. RF Shields can also be formed with or without tabs for pick and place machines, and “mouse” holes in specific positions to enable PCB trace patterns to cross in and out of the shield.