ASIC Or FPGA, How To Choose Between Them

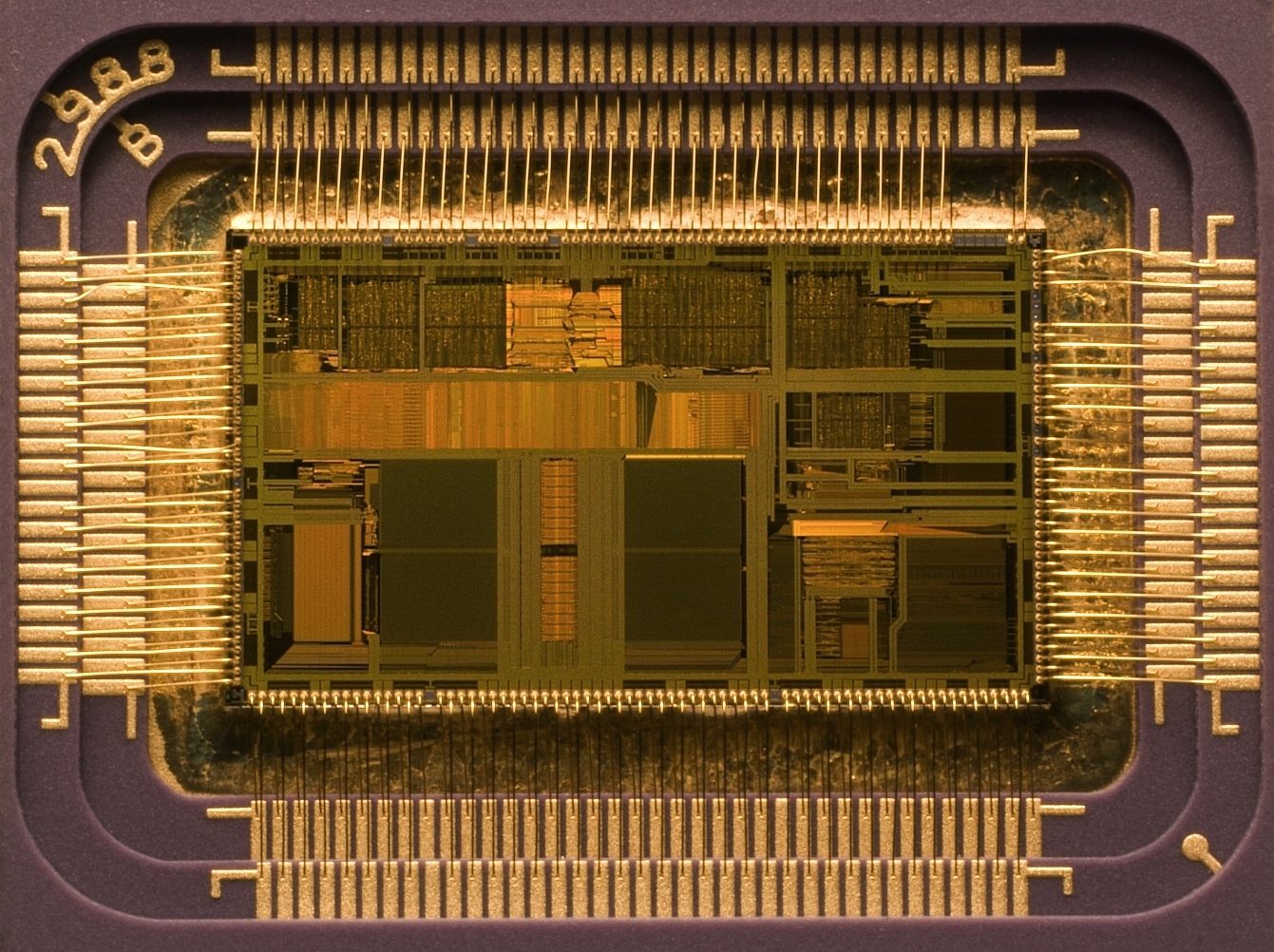

Application Specific Integrated Circuit (ASIC)

Application Specific Integrated Circuits are non-standard integrated circuits that are designed for a specific use or application. Here a complete system or product is integrated onto a chip and virtually no other components are required. Its function cannot be changed to anything else because its circuitry is made up of permanently connected in silicon. The cost of designing an ASIC is very high, NRE (Non-Recurring Engineering) cost, and therefore they tend to be reserved for high volume products. But can be very cost effective for many applications where they are produced in large scale.

ASICs are specific chips used to implement both analog and digital functionalities in high volume or high performance. ASICs are full custom requiring higher development costs, and as they are not reprogrammable and therefore a change requires again NRE payment. On the other side, ASICS is much denser, being possible to integrate different functionalities into one chip and therefore offer small size and low power solution.

Types of ASICs:

- Full-Custom

In this type, the complete IC design and developments are customized by the designer. Full-custom offers the highest performance and lowest part cost. The advantages of the full-custom design are reduced area (and therefore recurring component cost), better performance, increased reliability. The disadvantages of this type are increased design time, complexity, increased non-recurring engineering costs, design expense, the requirement of much higher skilled design team and highest risk.

- Standard-Cell–Based

ASIC manufacturer creates functional blocks with known electrical characteristics, such as propagation delay, capacitance, and inductance. Utilizing these functional blocks, standard cell of very high gate density and good electrical performance is designed. This gives a high degree of flexibility, provided that standard functions are able to meet the requirements. The significant advantage in Standard-Cell-Based ASICs is that this uses the manufacturer’s cell libraries that have been used in potentially hundreds of other design implementations. Standard cells produce a design density that is cost-effective, manufacturing time is also less, and they can also integrate IP cores and SRAM effectively.

- Gate-Array–Based

This type of ASIC is the least customizable. This type is ideal where a large number of standard functions are required which can be connected in a particular manner to meet the given requirement. Manufacturing lead time of Gate array-based ASICs is between two days and two weeks.

Field Programmable Gate Array (FPGA)

It is an integrated circuit which can be programmed to work as per the intended design, made up of thousands of Configurable Logic Blocks (CLBs) embedded in an ocean of programmable interconnects. They are not fully customizable, for example, one cannot add a specific analog block or integrate RF capability into an FPGA, those functionalities need to be implemented by external ICs

The FPGA design flow eliminates the complex and time-consuming floorplanning, place and route, timing analysis, and mask/re-spin stages of the project since the design logic is already synthesized to be placed onto an already verified, characterized FPGA device.

ASIC versus FPGA comparison

FPGA and ASICs provide different values to designers, and they must be carefully evaluated before choosing anyone over the other.

ASICs Advantages

- Small in size

An ASIC is designed with proper floor planning. So, the size of an ASIC designed for a specific application is always smaller as compared to other programmable devices. Small size consequently leads to advantages in speed and power consumption.

- No timing Issues

Digital logic switching, analog effects and communication between blocks in the chip is faster in ASIC.

- Less Power Consumption

ASIC consumes less power because logic operations are done within a chip; since smaller components have much smaller parasitic resistance, capacitance, and inductance.

- Fully developed and functional

ASIC is designed from scratch to the fully functional stage. After its manufacturing, no other configuration is required to be done.

ASIC Drawbacks:

- Not flexible

ASICs are made for a specific purpose. So, they are not flexible.

- Higher Cost

Only for higher-volume products, the production cost of ASIC is lower.

- Increased Time to Market

Increased time-to-market is the final drawback of ASIC. It is because designing an ASIC is very complex and time-consuming. Moreover, before marketing, ASIC must be tested thoroughly and if a fault is detected the IC has to be redesigned.

ASIC

FPGA

- A unique type of integrated circuit meant for a specific application which cannot be longer altered once created.

- Wastes very little material, recurring costs are low.

- Cost only affordable when it is produced in large quantity because of very high Non-Recurring Engineering (NRE cost)

- Can have complete analog circuitry

- Much more power is efficient than FPGAs. Power consumption of ASICs can be very minutely controlled and optimized.

- ASIC fabricated using the same process node can run at a much higher frequency than FPGAs since its circuit is optimized for its specific function.

- Are not suitable for research and development purposes, as they are not reconfigurable.

- Programmable integrated Circuit which function can be altered.

- Not efficient in terms of use of materials. A certain number of components are always wasted.

- Better than ASIC when building low volume production circuits. There is no NRE cost.

- Analog designs are not possible with FPGAs. Although FPGAs may contain specific analog hardware such as PLLs, ADC etc..

- Less energy efficient requires more power for the same function which ASIC can achieve at lower power.

- Limited in operating frequency compared to ASIC of similar process node. The routing and configurable logic eat up timing margin in FPGAs.

- Useful for research and development activities. Prototype fabrication using FPGA is affordable and fast.